Metal technology

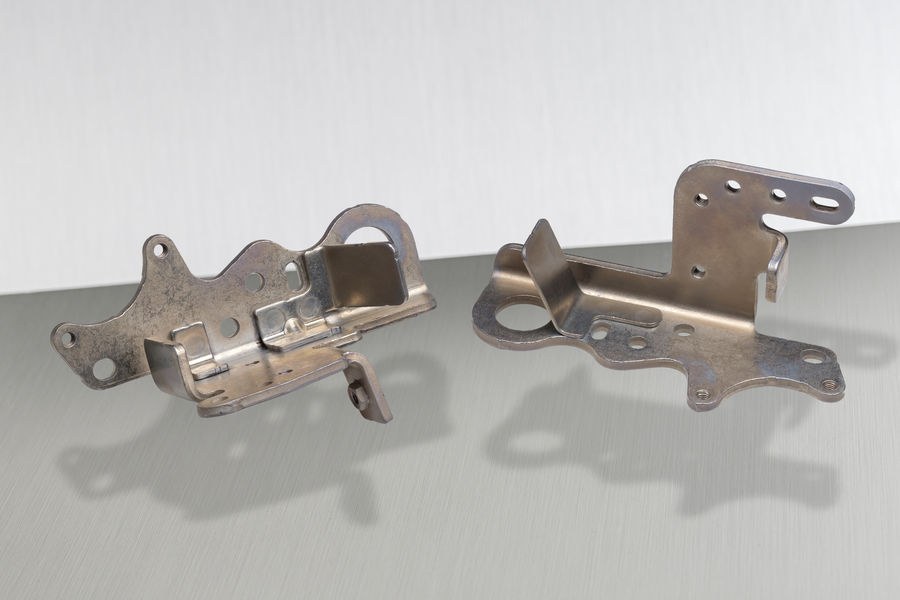

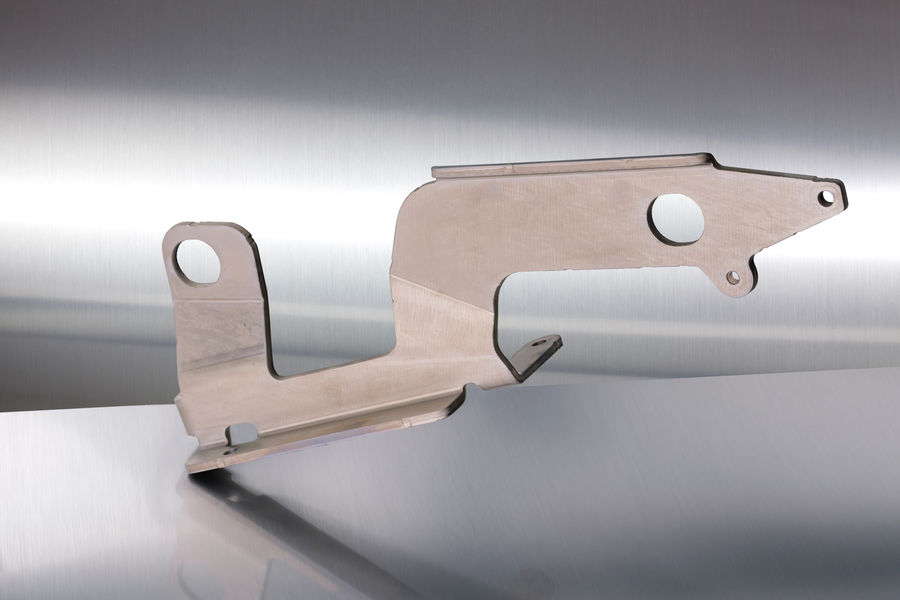

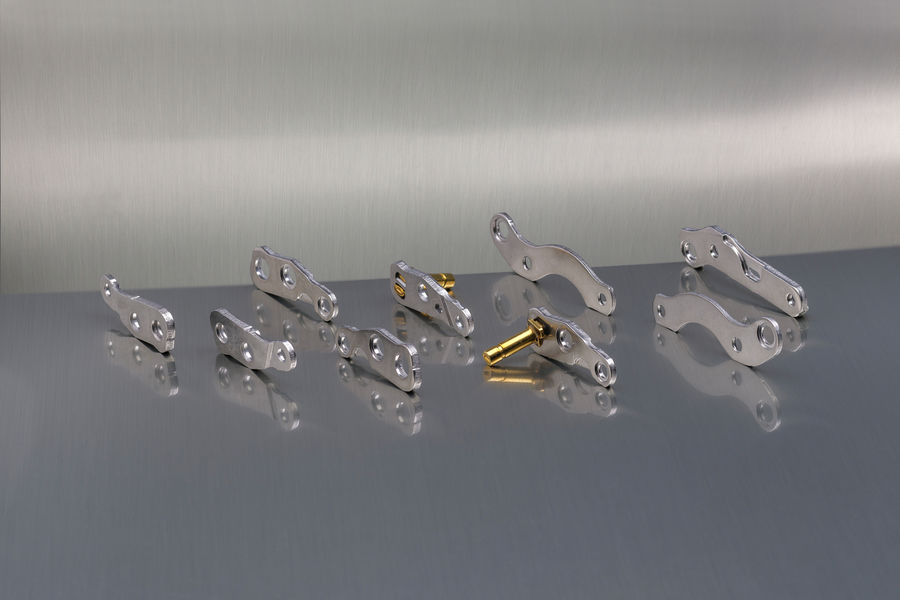

Punching and Forming technology

Punching parts, bent parts, welded assemblies.

Serial parts from 10,000 to 1,000,000 pieces a year.

We punch intricate holders, asymmetrical drawn parts, embossed pipe sockets, even flanges and complex covers with progressive compound tools.

We manufacture welding assemblies, welding parts and welding nuts in automated welding systems and at manual welding workstations.

We use state-of-the-art servo technology and state-of-the-art welding technology.

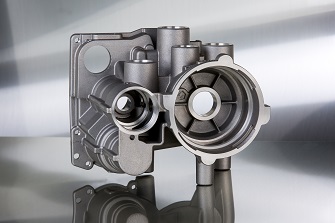

Machining technology

Turned parts, milled parts, complete machining of castings.

Serial parts from 500 to 250,000 pieces a year.

We produce precision components using CNC turning and milling technology with automated and manual equipping.

We use the latest CNC lathes with automated bar loading and advanced CNC machining centers with Fanuc control.

Industries

Valmet

Bosch

ZF

SKF

Nidec GPM

Alfred Raith

Baumer Hübner

TRUMPF

Schüco

Häfele

Knorr Bremse

BMW Motorrad

EBK

Siemens

Certificates

Automotive Quality Management System

Quality Management System

Environmental management system

Technical specifications

Excerpt:

14 punching presses with 40 to 400 t pressing force

20 CNC lathes

8 CNC milling machines

Automated welding system

2D laser cutting

Complete data under "Details", also available as download.

Engineering Design with SolidWorks

3D measuring machines

FEM simulations with ANSYS